Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

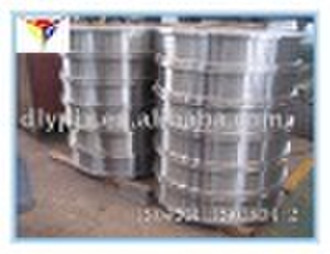

forged wheel

original price: 3 900 USD

Dalian, China

Production capacity:

12 Unit

yanfeng Zhang

Contact person

Basic Information

| Place of Origin | Liaoning China (Mainland) |

|---|---|

| Brand Name | Dalian Yipin |

| Model Number | OEM |

| Application | heavy machinery |

| Dimensions | 1050mm |

Feature of the forged wheel(Brazil) 1. MATERIAL: 42CrMo4 EN 10083/1 DIN 17212 2.weight: 1210 3.diameter: 1050 CYCLE OF THE MECHANICAL PROCESING AND THERMIC TREATMENTS 1. Normalizing of the raw forged steel 2. Rolling of the forged steel by turning 3. Ultrasonic inspection 4. Roughing-out of the wheel with about 2mm swarf 5. Hardening and tempering of the wheel 6. Ultrasonic inspection 7. Pre-finishing turning 8. Preheating in the furnace at 200-220°C, hardening at an average frequency, slow tempering (20-25°C /h), minimum hardness 300HB, hardening depth 10mm 9. Finishing turing, taking care of the concentricity and squareness among the hole, a side of the wheel and the rope face Terms of payment: 30% down payment, 70% after receives the following documents: -Report of dimensional test -Certificate of quality of raw material -Report of all the thermal process used to manufacture the forged wheels -Pictures of the wheels concluded and packed Time of delivery: 90 days from the date of down payment 9. Welcome to contact us:Company: Dalian Yipin Machinery Manufacturing Co., LtdAddress: Maoyingzi, Ganjingzi District, Dalian, ChinaTel: 86-411-39890106Fax: 86-411-87112877

Delivery terms and packaging

Packaging Detail: wooden case/wooden pallet/according to your requirement Delivery Detail: 90 days from the date of down payment

Port: Dalian, China

Payment term

Telegraphic transfer

-

Payment Methods

We accept: